WHY UV SHEATHED HANDLES,

WHY NOW

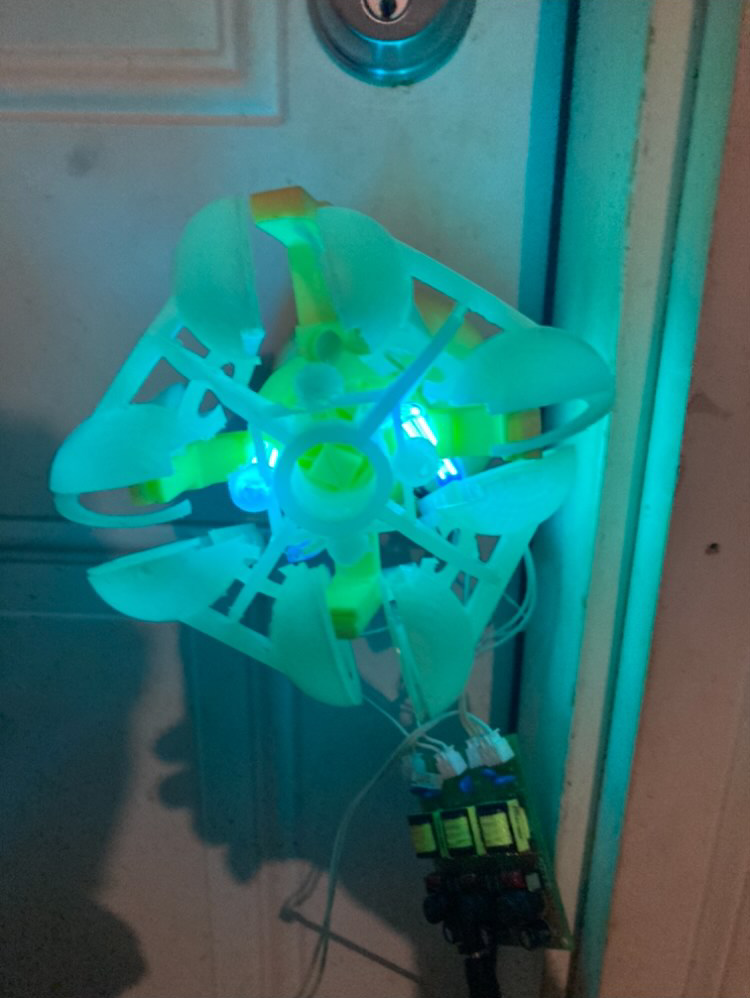

By mid April 2020 Covid19 had already ravaged the global sense of security as millions upon millions suffered the inconvenience of isolation, masks, shortages of gloves with no vaccine yet issued. My own Uv Railed Doorknob had undergone the public experiment of a modified rubber handball adaptor to see if that Matierial could attach a Uv light Petg handle to another handle via a rubber interface. Successfully as theorized on Facebook it had. With the media on the highest of health alerts I rapidly designed my first facsimile handball adaptor with a forked end to attach my UV slots transparent Handle and assembled the 3d print prototypes and professionally photographed then for the World Intellectual Property Organization.

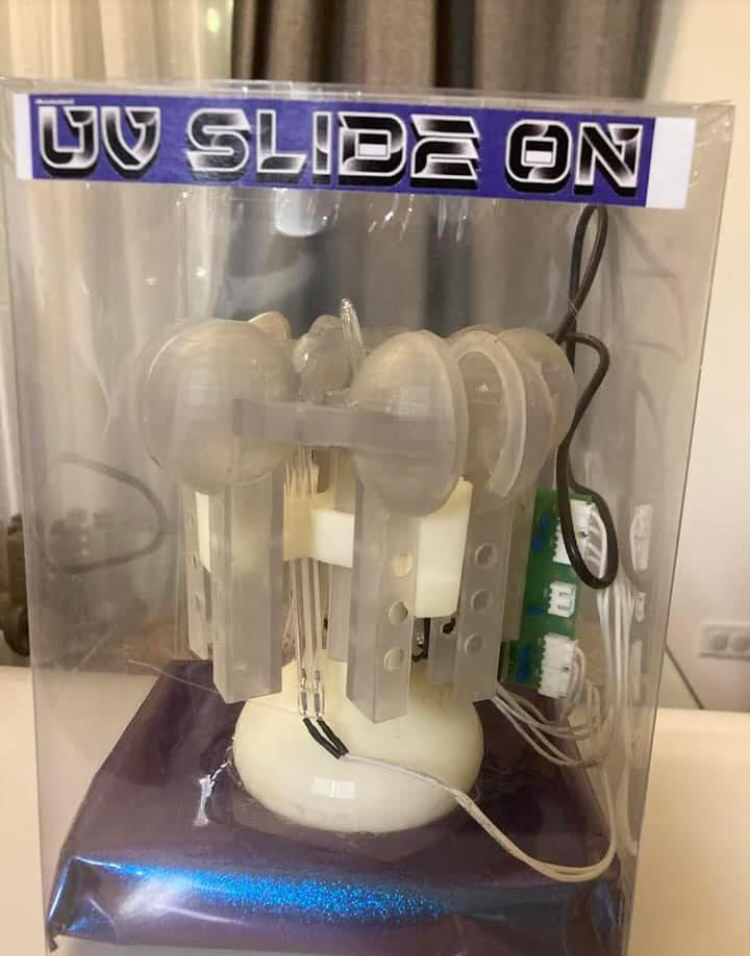

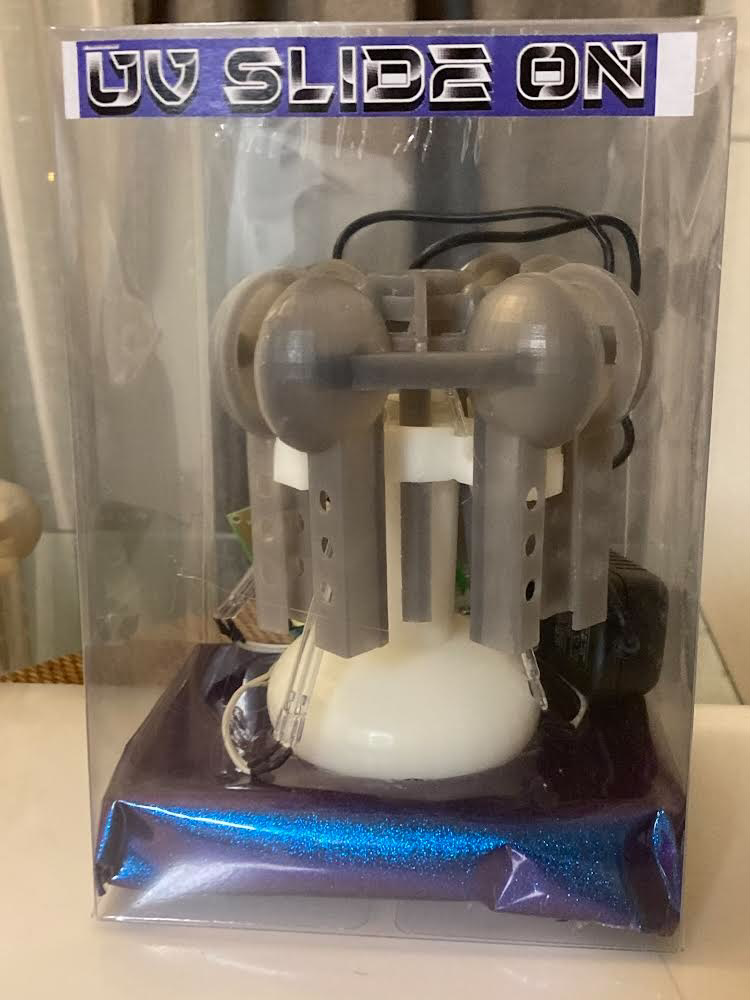

The advantages of installation were clear – its faster and less problematic to remove. Other advantages were if a repair was needed uv lights could be exchanged as could a ballast. Plus proliferation time, if a building with 2000 handles needing uv ordered these months of labor would be reduced to two hours of draping the rubber instead of endless screwdriving. One must consider how often handles on doors are changed , ofter never. My mothers NYC apartment has the same front door handle for over 40 years even with several million dollar renovations by owners.

With 47 countries applied for in the design patent i knew now the diversity of handles globally needed an adaptor variegation to attach to the vast majority of market and in the following year i diversified my adaptors to the extent of a torus , spherical and cylindrical to embrace the world market in a drillable TPU unit that can be customized after order size.